About the Awards

The Sustainable Packaging Coalition recognizes meaningful contributions and advancements towards more sustainable packaging through the annual SPC Innovator Awards. The awards celebrate and showcase the outstanding collaboration behind extraordinary advancements in sustainability.

The SPC Innovator Awards reflect GreenBlue’s mission to foster education, collaboration, and action to advance sustainable packaging. The awards aim to:

- Educate the SPC membership and broader sustainability community on the work being done to improve the environmental performance of packaging and to scale packaging systems change

- Highlight the collaboration that makes leading innovations in our community possible

- Inspire action by highlighting market-ready packaging improvements and effective partnerships, thereby driving more companies to adopt sustainable packaging innovations

2024 SPC Innovator Awards

Sponsored by Trayak

These groundbreaking technologies were selected based on a rigorous selection criteria, assessed by our esteemed judges. We applaud all three winners for their breakthrough innovations. The SPC Innovator Awards recognize meaningful contributions and advancements towards more sustainable packaging, showcasing the outstanding collaboration behind extraordinary advancements in sustainability.

The 2024 SPC Innovator Awards would not be possible without our sponsor, Trayak.

2024 SPC Innovator Award Winners

Chocal Packaging Solutions

Innovation in a Product or Material

Chocal Paper Blister

Innovation in a Recovery Technology or Practice

Innovation in a Recovery Technology or Practice

RafCycle™ by UPM Raflatac is the original label release liner recycling service

Orora Packaging Solutions

Innovation in an Overall Packaging System

Jarbot Reusable Packaging System

Award Categories

Innovation in a product or material

- Recognize breakthroughs in the procurement and use of more sustainable materials, including new materials, improvements to conventional materials, improvements to sourcing practices, and novel uses of materials in challenging applications

- Recognize breakthroughs in efficiency, including reductions in material usage, process improvements enabled by changes in packaging design, and improvements to volumetric/cube utilization and transportation efficiency

- Recognize design improvements that enable greater compatibility with existing recovery infrastructure

Innovation in a recovery technology or practice

- Recognize breakthroughs in the quantity and/or quality of recovered packaging through enhancements to recovery programs and/or infrastructure

Recognize partnerships whose aim is to advance recovery practices and/or participation - Recognize efforts to create end markets for difficult-to-recycle materials

Innovation in an overall packaging system

- Recognize breakthroughs that reduce the need for single-use packaging, such as through reuse and refill offerings

- Recognize design improvements that solve broader sustainability challenges, such as the prevention of food waste through improved packaging formats

- Recognize efforts to educate consumers and drive specific behaviors, such as through advancements in labeling paired with education campaigns

- Recognize breakthroughs that radically break the mold of a current packaging category through wholesale redesign

Submission Process

The SPC Innovator Awards are open to SPC member companies only. Each member company may submit a maximum of three innovations across the three award categories.

The submission period opened 10/11 and will close at 5pm ET on Friday, December 8th.

All material submitted to the SPC Innovator Awards program may be used as part of the decision-making or communications about an entry; confidential or proprietary information should not be submitted.

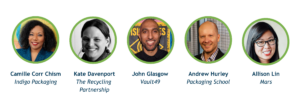

Innovator Award Judges

The SPC Innovator Awards are judged by a committee consisting of SPC Executive Committee members, GreenBlue’s Executive Director and project staff, as well as external guest judges from university, consultancy, or design agency representative with significant expertise in a particular category.

We’re excited to have a stellar lineup of guest judges who bring insights from their work in the worlds of recycling, branding and design, lean manufacturing and returnables, packaging curriculum, and CPG!