The Sustainable Packaging Coalition works to improve packaging circularity, and we do that in part by helping our members tackle real-world challenges with hard-to-recycle materials formats, like Polyethylene (PE) film. While the current system for collecting films isn’t perfect, today Store Drop-off (SDO) is the most viable path for diverting these materials from landfills and our environment.

To substantiate the current Store Drop-off system, we need current, high-quality data demonstrating access to collection, actual collection, and the reprocessing of these materials. Since consumer access to Store-drop off recycling is the first piece of this puzzle, we’re sharing our research insights on national access to these collection points.

According to our April 2025 research, we found that:

- 70.72% of U.S. consumers are within a 3-mile driving radius of Store Drop-off (SDO) collection for Polyethylene (PE) film

- 92.12% are within a 10-mile driving radius of SDO collection for PE film

- 97.86% are within a 20-mile driving radius of SDO collection for PE film

While these results are encouraging, it’s important to note that access is just one piece of the puzzle. Proof of access does not ensure consumer participation, nor does it substantiate that these materials are collected and reprocessed. There is significant work ahead to substantiate the system as a whole, but this research establishes a clearer picture of where access exists today.

New Data Highlights Widespread Access for Most Consumers

In 2022, the Sustainable Packaging Coalition (SPC) published the results of the Film & Bag study in California, which provided access data to Store Drop-off collection in the state. Driven by the compelling findings from the California study, SPC was motivated to conduct a new nationwide study.

SPC’s national access study was completed in early April 2025 and found that a significant portion of the U.S. population has access to Store Drop-off collection: 70.72% of U.S. consumers are within a 3-mile driving radius of Store Drop-off (SDO) collection for Polyethylene (PE) film, 92.12% are within a 10-mile radius and 97.86% are within a 20-mile radius, at a 95% confidence level.

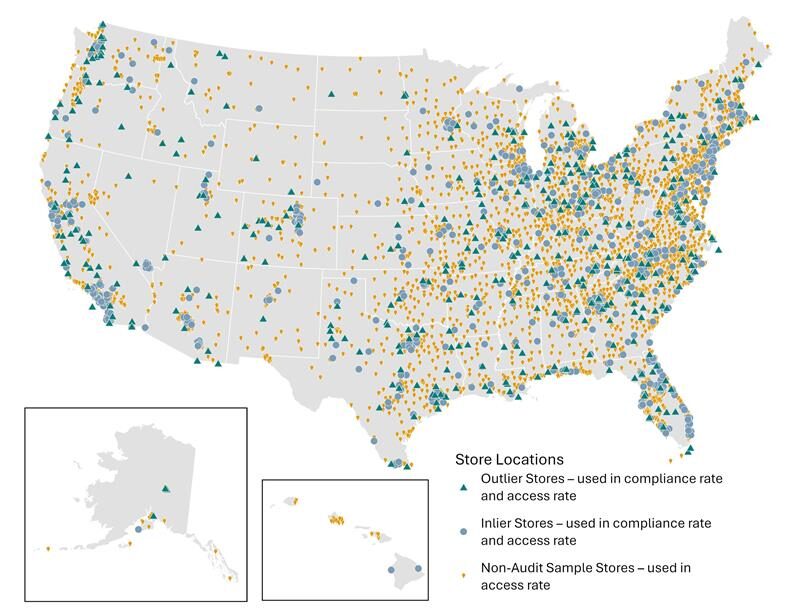

Below is the mapping of the store locations identified in the study:

Our study found that 70.72% of U.S. consumers are within a 3-mile driving radius of a Store Drop-off (SDO) collection point for Polyethylene (PE) film.

How Was This Study Conducted?

The study, which was commissioned by the Sustainable Packaging Coalition (SPC) and conducted by Resource Recycling Systems (RRS) sought to develop a rigorous methodology for measuring and substantiating national consumer access to Store Drop-off collection points for PE film.

The study employed a multi-faceted methodology:

- Sample Selection: A stratified random sample of stores was drawn from all locations believed to offer Store Drop-off.

- Population Data: 2020 U.S. Census block group-level population data was used to assess access.

- Access Radius: The study measured a unique population within 3, 10, and 20 miles driving radius of each store.

- Monte Carlo Simulation: The study simulated store compliance based on real-world uncertainty and variation models repeated 1,000 times.

- Base Access Determination: A national consumer access rate to Store Drop-off was determined using data provided by participating retailers on over 10,000 verified store locations with bins. For retailers that submitted audit data, their number of store locations was adjusted by the rate of non-compliance found in their audit, calculated by comparing the number of stores of non-compliance (not verified during audit) with the total number of stores listed.

- Adjusting Access: Retailers that did not conduct a store-level audit were adjusted by a fixed percentage based on the average non-compliance rate of participating retailers.

Challenges to Assessing Store Drop-off Access

The study identified the following limitations and challenges:

- Program Management Variability: There were significant differences in how retailers manage their SDO programs.

- Contamination Handling: Most retailers ask associates to conduct a visual inspection of bins. If considered too contaminated, materials are disposed of in trash rather than sent out for recycling.

- Tracking Limitations: There is no standardized system for tracking the volume of collected materials that end up disposed versus recycled. Waste contracts are typically managed at the corporate level, with store locations lacking visibility into recycled volumes.

- Audit Challenges: Stores have customized approaches to SDO, network security, and blackout periods, all of which directly interfered with the store-level audit process.

- Extended Producer Responsibility (EPR) Risks: SDO programs in EPR states may be at risk of operational challenges due to additional costs and reporting requirements.

Next Steps for Assessing Film Recycling Access

The study successfully established a methodology for determining national consumer access to Store Drop-off recycling for PE film, finding that the majority of Americans have access within reasonable distances; however, it also revealed significant operational challenges in the implementation and management of Store Drop-off programs.

Through the SDO Film Recovery Collaborative, SPC is committed to address these challenges. We’ll take learning from our access study and plan to spearhead the following projects:

- Research: Consumer awareness on SDO film programs by September 2025

SPC will commission a consumer survey to be conducted by an external vendor to better understand what consumers know and think about Store Drop-off with the purpose of being an educational resource for our members.

- Resource: Guidelines for retailers on SDO film programs by November 2025

SPC will produce a resource designed to highlight the best practices of Store Drop-off collection programs for films to support retailers in overcoming internal barriers to SDO implementation and improvement.

Within our parent nonprofit GreenBlue’s network, the results of this study will also be used by the How2Recycle team to substantiate the Store Drop-off label.

SPC is also enthusiastic to collaborate with industry peers, sharing results from this study with the Plastics Industry Association (PLASTICS) for their plasticfilmrecycling search directory, in a joint effort to provide consumers with information on where to find a recycling drop-off location for plastic film.

Of course, access is just one piece of the recyclability puzzle. GreenBlue’s the Recycled Material Standard (RMS) is in the process of planning third-party chain of custody audits and pilot certifications with select retailers and recyclers in the SDO stream. These audits will provide us with more data on the reprocessing of collected film materials.

Across all GreenBlue projects, we strive to listen, lead where we can, and maintain our long-term vision of building a world where the materials economy sustainably strengthens our environment. While we don’t own the Store Drop-off system, we understand its current role in achieving a circular materials economy and hope to advance the insights that produce a more transparent, trustworthy system for film recovery.

To get involved, SPC members can join our SDO Film Recovery Collaborative today.